Energy Management

GOAL

THE POWER OF PULP

With the growing demand for natural, fiber-based products such as tissue and towels, Mercer’s pulp mills provide products made from a renewable resource, wood. Kraft pulp is biodegradable and conducive to a lower-carbon footprint, but is also a superior alternative to plastics in packaging and fabrics in hygiene products.

The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp which consists of cellulose fibers, the main component of paper. Our pulp mill facilities are among Europe and North America’s newest and most modern, offering us competitive manufacturing costs and efficiency advantages.

ENERGY EFFICIENCY AT OUR PULP MILLS

Our pulp mills are energy self-reliant with minimal purchases of third-party electricity. We have invested significantly in cogeneration systems, allowing us to generate, use, and sell surplus bioenergy, supporting the renewable energy transition. Mercer has multiple energy management systems in place, including ISO 50001 certification at all German mills and an internal project coordinator network which tracks energy key performance indicators and shares best practices between mills.

RENEWABLE ENERGY FROM THE KRAFT PULPING PROCESS

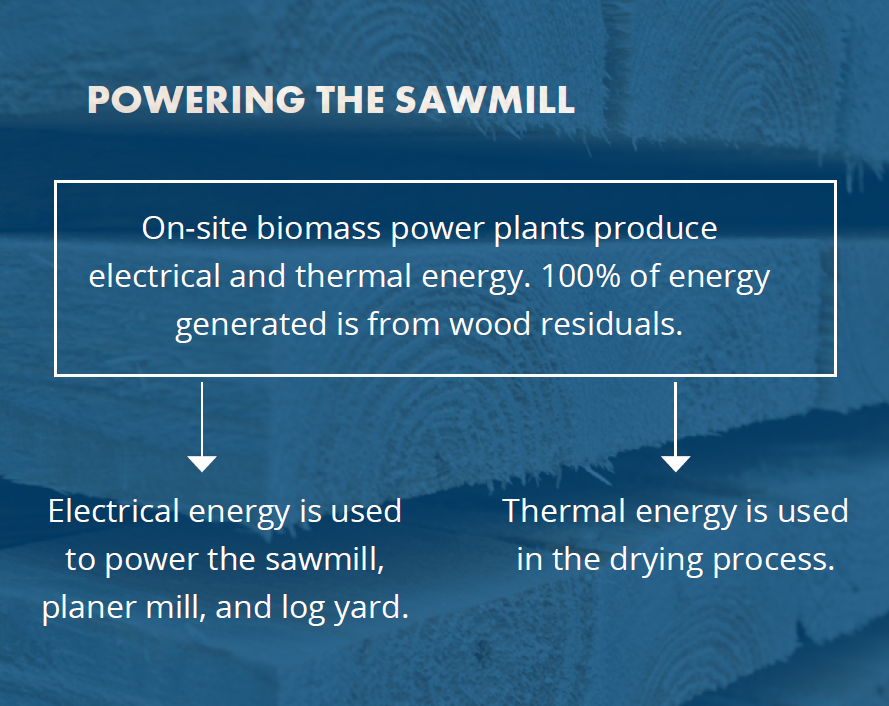

ENERGY EFFICIENCY AT MERCER’S SAWMILLS

Mercer’s sawmills operate biomass cogeneration plants that uses sawmill byproducts to produce both thermal energy for drying operations and electricity fed into the public grid. This approach contributes to Mercer and global energy transition and sustainable development goals. This begins with diligent management of the use of energy. Both of Mercer’s sawmills are ISO 50001 certified, which provides a framework to track energy use and implement energy-saving initiatives. Some of these initiatives include using frequency converters to better match energy consumption to demand, heat exchangers to recover and reuse waste heat, as well as the replacement of conventional lighting with LED lighting throughout the facilities.

Energy savings can also be achieved through logistical improvements. At Mercer Timber Products, Mercer realized higher product yields through the combination of the compressed air systems of the sawmill and the planer mill. Another example included optimizing the flow of raw materials to reduce the number of empty truck runs.

REDUCTION IN ELECTRICAL ENERGY CONSUMPTION FROM 2023

STEAM AND BIOENERGY PRODUCED

EFFICIENCY THROUGH TECHNOLOGY

Mercer’s sawmills utilize sophisticated energy monitoring systems with numerous measurement points to track electricity and fuel consumption. This data enables the identification of energy consumption thresholds and highlights opportunities for efficiency improvements. By increasingly integrating real-time monitoring technologies, Mercer’s sawmills are able to optimize energy use relative to production output.

2024 MILESTONES

This year, Mercer Holz continued expanding its rail capabilities, focusing on optimizing roundwood deliveries alongside its industry-leading wood procurement activities. Investments in modern railcars and infrastructure underscore the company’s dedication to sustainable growth, even as challenges such as aging rail networks and rising demand test the industry.

WHY RAIL MATTERS

- Sustainability: Rail emits far less CO2 than road transport. Mercer’s transition to rail is one key action in our Climate Transition Plan.

- Efficiency: Custom railcars minimize trips and save resources.

- Reliability: Rail ensures timely and safe delivery.

Looking ahead, Mercer Holz remains committed to strengthening rail logistics, supporting regional development, and leading climate-conscious innovation in timber transport.

MERCER TIMBER PRODUCTS TESTS 16-TONNE ELECTRIC FORKLIFT WITH LITHIUM-ION TECHNOLOGY

As part of its e-mobility strategy, Mercer recently tested a 16-tonne electric forklift truck with the latest lithium-ion technology at Mercer Timber Products in Germany. The test phase was designed to assess the truck’s performance and practicality under real-world conditions.

FOCUS ON EFFICIENCY AND FLEXIBILITY

The electric forklift truck performed impressively in the test. With a battery capacity of up to 230 kWh, it was able to operate for eight hours at a time. The newly constructed charging infrastructure, with charging points of up to 300 kW, makes it possible to charge the battery from 30% to 80% in just 30 minutes. This fast-charging capability makes the electric forklift particularly attractive for multi-shift operations and offers the potential to sustainably increase the flexibility and productivity of the sawmill.

The insights gained from the test deployment are helping Mercer Timber Products plan the conversion of its forklift fleet. The purchase of the first electric forklift is scheduled for 2025. Simultaneously, the necessary charging infrastructure is being built to ensure a smooth transition. Mercer aims to advance our e-mobility strategy by continuing to prioritize electric alternatives to fossil fuel based mobile equipment when making new purchases.

President and Chief Executive Officer