Circular Bioeconomy and Resource Use

WASTE MANAGEMENT

Based on a quest to substitute non-renewable fossil fuels with sustainable alternatives from biomass products, the “take-make-dispose” approach is supplanted by a “reduce, reuse, recycle” mantra. At Mercer, the transition to a circular bioeconomy is rooted in nature-based solutions such as wood from forests that are well managed. Our pulp mills generate process waste that includes wood ash, recausticizing dregs, and lime waste deposited in our operations’ landfills. Our mills generate minimal amounts of hazardous waste that is managed and disposed of safely and reported on in accordance with relevant local laws and regulations.

Mercer has reduced our pulp mill process waste sent to landfill per tonne of pulp by 24% since 2019, with 18% of this reduction attributed to 2024. These reductions are due to intentional and proactive initiatives at a variety of our mills to find alternative uses for our pulp mill process waste including land applications of ash, biosolids, or lime for agricultural purposes and road construction.

GOAL

Refer to the Appendix for relevant scope, definitions and methodology for waste management and resource efficiency targets and progress.

RESOURCE CIRCULARITY AND WASTE REDUCTION

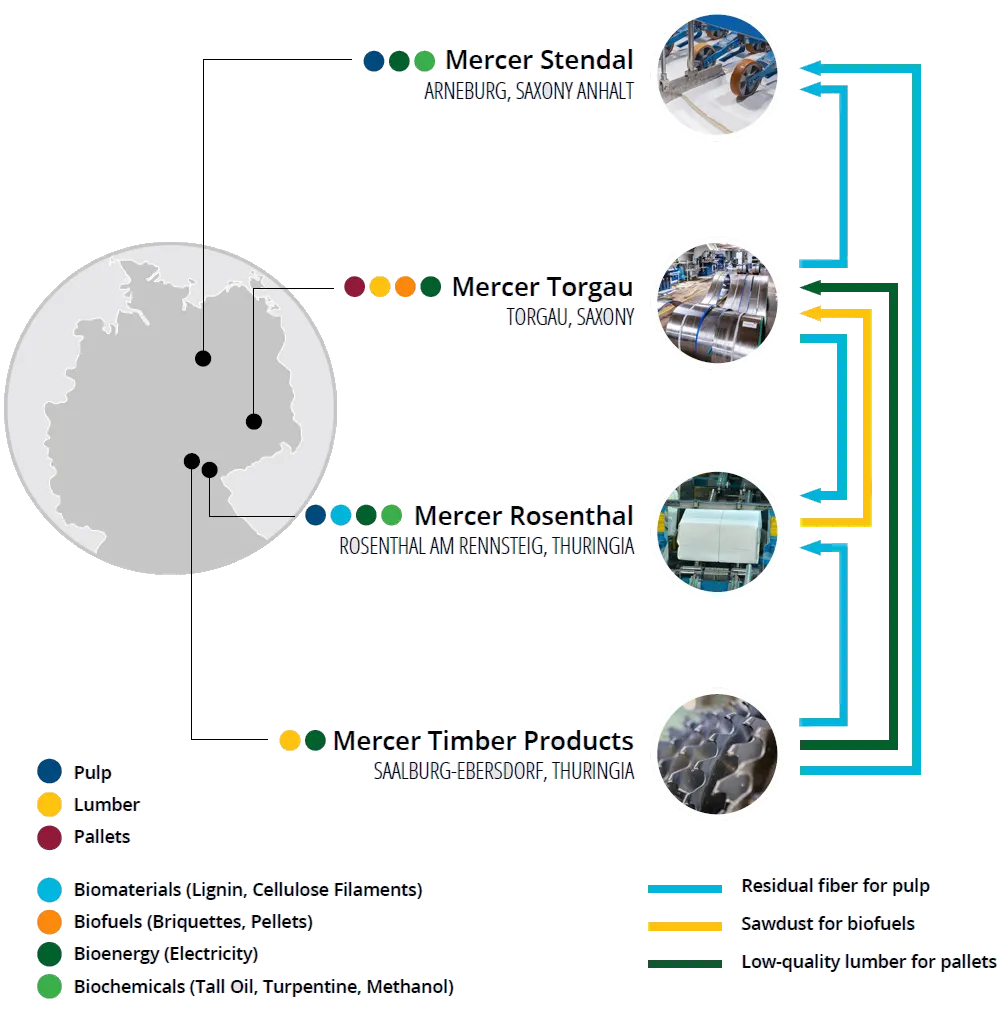

Mercer’s German operations reflect the synergistic efficiencies gained through careful collaboration and logistical planning. This coordination has led to minimized waste as well as efficiencies related to transportation and a more efficient and streamlined supply chain.

Chief Operating Officer Wood Products

CIRCULARITY AT OUR SAWMILLS

Maximizing value from every log is central to our sawmills’ circular approach. This optimization begins in the forest, where each log is strategically allocated to the most suitable mill based on its size, shape, and quality. Upon arrival, advanced scanning technology determines the highest-value end-use for each log, dictating the optimal cutting patterns and resulting products. As logs are processed, residual fiber such as bark, wood chips, and sawdust is generated. A portion of these byproducts is then transferred to Mercer’s pulp mills for conversion into high-quality pulp. The remaining residuals fuel on-site power plants, generating enough energy to fully power the sawmills and provide local grids with bioenergy. Mercer aims to utilize raw fiber inputs as much as possible before its end-of-life.

LIGNIN: A NATURAL ADVANCEMENT TOWARD INNOVATION IN THE MERCER VALUE CHAIN

Lignin, a valuable raw material extracted as part of processing wood cellulose, can be used to manufacture anything from plastics and paints to medicines and natural aromatics. Mercer’s state-of-the-art pilot Lignin Center in Rosenthal, the first of its kind in Germany, showcases our commitment to advancing the circular bioeconomy and substituting fossil-based products with bio-based materials. The versatility of lignin in numerous applications that today still rely on fossil-based materials is a step forward in helping our value chain to reduce emissions and achieve our climate ambitions.

BIOFUELS FROM SUSTAINABLY MANAGED FORESTS

At our Mercer Torgau mill, full utilization, fiber efficiency, and value-driven log use are top priorities, resulting in a highly efficient and circular business model. Every part of the tree is utilized to create a range of bioproducts, including pallets, lumber, briquettes, and pellets, as well as wood residuals like sawdust and wood chips. Only wood from responsible sources is processed, and all of the wood and pellets are free of bark, waste wood, additives, and binders. In fact, Mercer Torgau was one of the first suppliers to have its wood briquettes and pellets certified according to ENplus, complying with its highest quality class A1 certification based on the DIN EN ISO 17225-3 standard.

IMPROVING YIELDS AND EFFICIENCY THROUGH TECHNOLOGY

Mercer leverages technology to maximize the value from wood lots by optimizing the annual residuals from the production process. Mercer Timber Products’ state-of-the-art planer mill can grade up to 100 different grades of wood and is complemented with a scanner that scans the complete board and calculates the maximum cut value. This allows Mercer to pre-sort different grades intended for different markets around the world more efficiently.